Let Numbers Speak about Our Strong Production Capabilities

See through Polyking’s numbers that we are your second-to-none partner for custom wholesale bags.

Bags Manufacturing

Owning skilled workers plus advanced automated equipment means that Polyking can complete your customized bag order with high quality and short lead time.

Efficient

Precise

Labor-saving

STEP 01

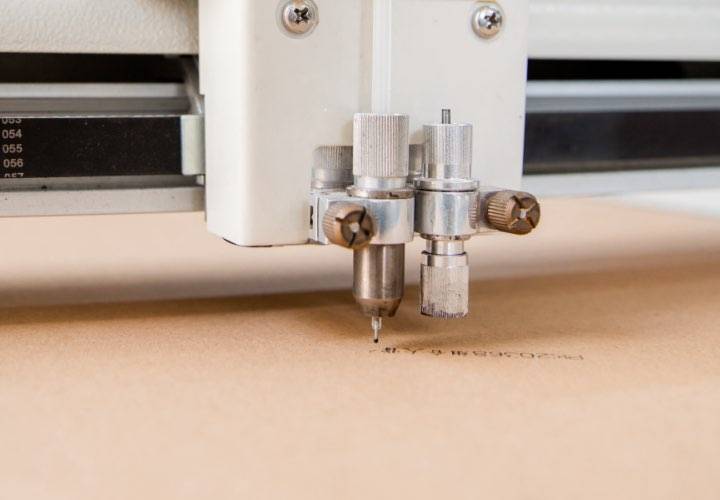

Paper Pattern Cutting

We use advanced machines for paper pattern cutting to ensure consistent and accurate cuts. This facilitates subsequent sample production and material cutting.

STEP 02

Knife Molds Customization

With proximity and long-term partnerships with reliable tooling factories, we’re able to secure high-quality knife molds with ease that help reduce production time.

STEP 03

Fabric Cutting

For faster and more efficient production of custom bags, we utilize the latest cutting machines, presses, and laser cutting machines to handle precision material cutting. This also reduces labor costs, allowing us to provide competitively-priced custom bags.

STEP 04

Bag Decoration

Our in-house print shop is equipped with cutting-edge printing machines to speed up production and provide eco-friendly and accurate prints while reducing costs. These types of equipment include heat sublimation transfer machines and fabric printers.

STEP 05

Sewing

With the latest pattern machines and sewing machines, our talented workers skillfully sew your custom bags with efficiency and durability.

STEP 06

Quality Inspection

Every finished custom bag goes through a needle detector, preventing broken needles from staying on the completed bags. Additionally, our quality improvement team does a sample check to review these custom bags’ appearance, workmanship, and performance before shipment.